Blisters may appear in the casting process of automobile wheels, and it is easy to have gaps in the process of pressing and riveting, which is difficult to distinguish with the naked eye. If the air tightness test is not performed, the performance of the car's hub will not guarantee driving safety. Therefore, the airtightness of the hub is an important indicator to measure the performance of the hub. Therefore, the airtightness detection is of great significance for the exercise of the vehicle.

The airtightness tester can be used to test the airtightness of the hub. This is a airtightness tester that uses a pressure drop method and uses compressed air as a test medium.

Generally, the detection pressure of 110KPA is adopted, the inflation time is 4S, the stabilization time is 3S, the test time is 5S, and the leakage value is not more than 70PA.

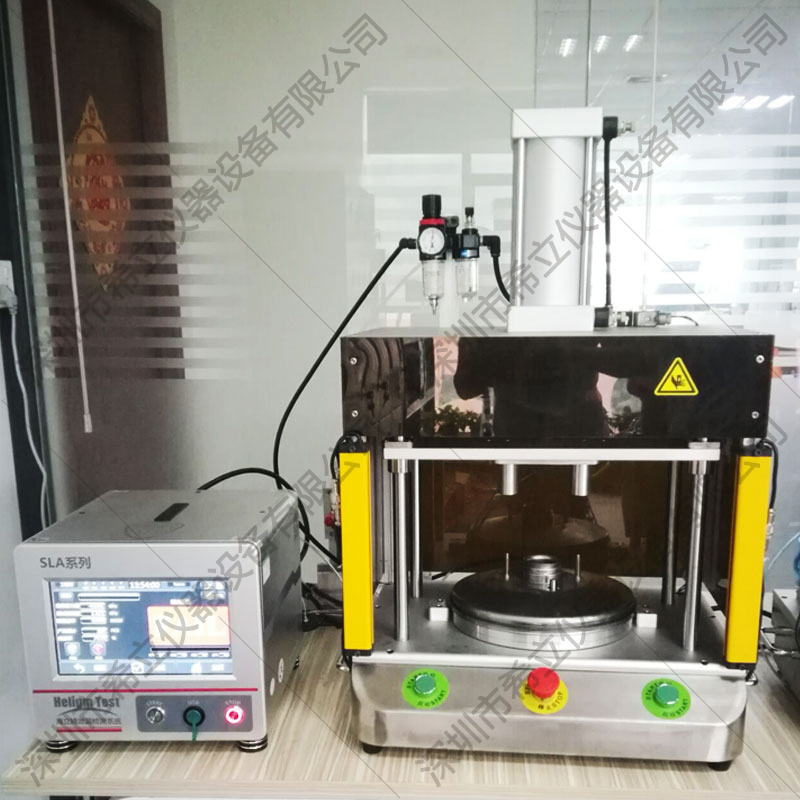

As shown in the figure below, the airtightness detector is applied to the hub airtightness inspection site.